Simuflight’s PC-12 Simulator: A New Era in Advanced Flight TrainingI am a heading

In a recent Coffee with the Editor session, held at Simuflight in Johannesburg, Managing Director Alfredo Schulz and Project Manager Chris Palfreyman shared insights into the groundbreaking PC-12 simulator project. This state-of-the-art training tool is currently being assembled at their Midrand facility by Aviamech, the group’s simulator engineering company, marking a significant milestone in aviation training in South Africa.

Simuflight, a trusted name

For readers of African Pilot, Simuflight is a familiar name, having established itself as a leading advanced Aviation Training Organisation (ATO) over the past 23 years. However, for the new editor, this visit offered a deeper look into the company’s history and expertise.

Simuflight operates in a niche segment, focusing on pilots who are already qualified and seeking type ratings to enhance their employability and career progression. Unlike entry-level flight schools that train aspiring pilots from scratch, Simuflight caters to corporate clients and experienced pilots looking to transition into new aircraft types.

Simuflight’s existing simulator-based training programs include type ratings for the Caravan 208, a crucial starting point for many young commercial pilots. Over the years, they have expanded their offerings to include the King Air 200 and their flagship training program, the King Air 1900. While Boeing 737 training has been part of their portfolio, that program is currently dormant. However, the biggest excitement at Simuflight in 2025 revolves around the highly anticipated PC-12 simulator.

The Journey to the PC-12 Simulator

The concept for a PC-12 flight simulator was first envisioned 12 to 14 years ago, when industry professionals expressed the need for such a training tool. However, at the time, the project faced significant hurdles—most notably, the lack of a suitable airframe. The breakthrough came two and a half years ago when Alfredo Schulz discovered an available PC-12 airframe, which became the foundation for this ambitious initiative.

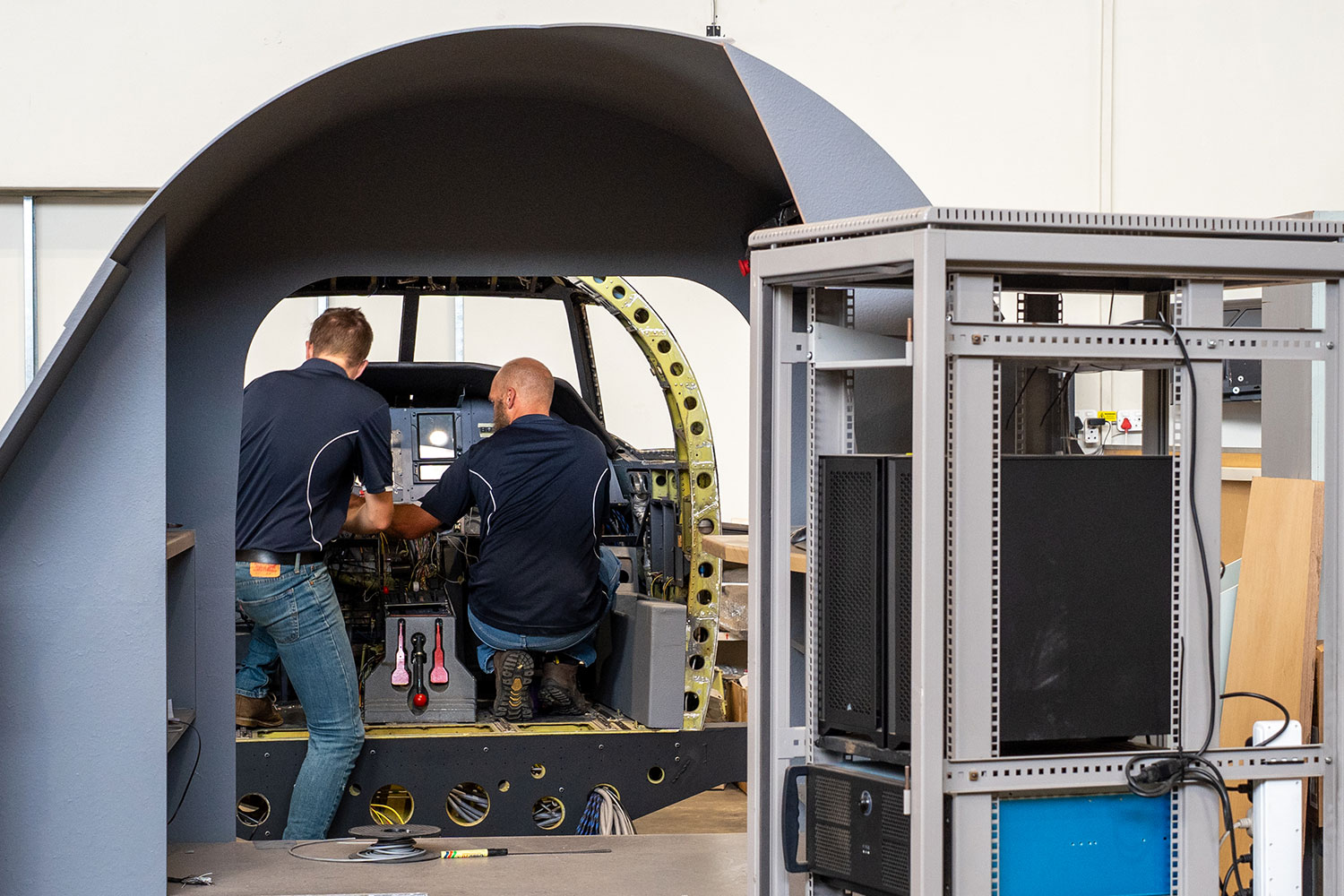

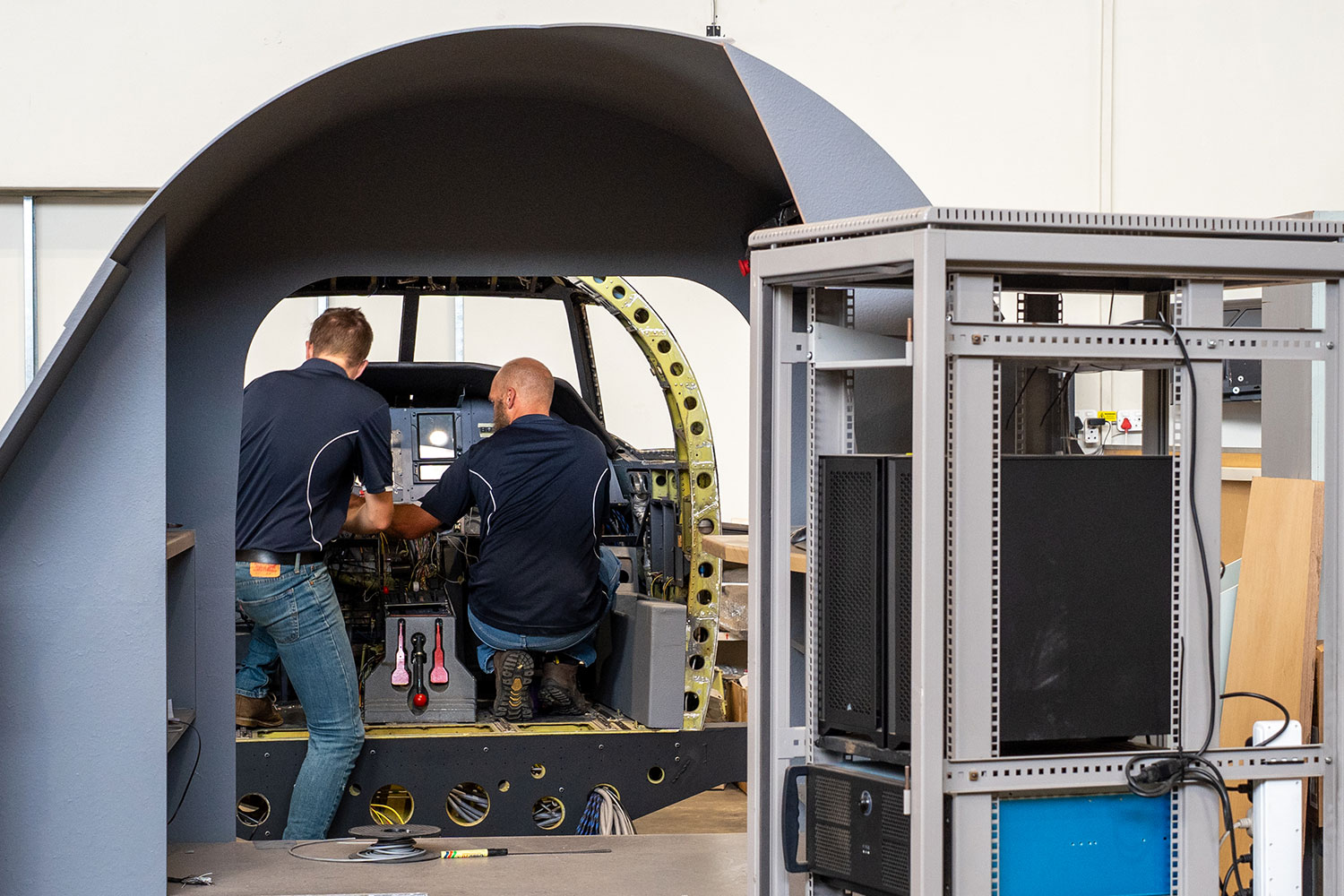

Once the airframe was secured, Aviamech’s engineering team embarked on an extensive design phase in December 2023. The challenge was to integrate Aviamech’s proprietary electronics, instrument panels, and software into the cockpit. By mid-2024, the design phase was complete, paving the way for the manufacturing and assembly process.

The Importance of Realism in Training

The simulator, designed to provide pilots with an authentic training experience, is built using a real PC-12 cockpit section to ensure absolute accuracy in form, feel, and function.

Chris highlights that integrating an original airframe into the simulator is key to developing muscle memory among pilots. “All dimensions, distances, and relationships between controls are exactly as they would be in the real aircraft,” he explains. “This is crucial for effective training.” The project began with a full 3D design using modern CAD software to ensure that each component fits seamlessly during the manufacturing phase. This meticulous design and planning prevents time-consuming reworks and ensures a smooth assembly process.

The simulator will incorporate both original aircraft components and custom-built parts.

One of the most intricate pieces being fabricated is the Overhead Panel, a crucial component controlling the aircraft’s electrical systems. “The switches and circuit breakers function exactly as they would in the actual aircraft, including the ability to break electrical flow manually,” Chris highlights. Even the illumination and backlighting mimic the original PC-12 systems.

Avionics and Future Upgrades

The avionics installed in the simulator will match the original PC-12 Type 47, commonly referred to as the Legacy model. These will be computer-generated but will accurately replicate the real aircraft’s avionics suite. The design also incorporates the potential for future upgrades, allowing for an easy transition to more modern avionics configurations. “We have built a growth path into the design,” added Chris. “The simulator can be upgraded to include the latest glass cockpit without altering the airframe.”

Advanced Computing for Ultra-Realistic Simulation

At the heart of the simulator is a powerful network of computers, each assigned a specific function. One system manages aerodynamic and scenery modelling, another controls the visuals, and two others drive the cockpit’s instruments. An Instructor Operating Station (IOS) is also included, allowing trainers to manipulate various in-flight scenarios. “Instructors can simulate engine failures, landing gear malfunctions, and other emergency situations to ensure pilots are prepared for real-world challenges,” Chris explains.

Motion and Control Systems

The simulator is not equipped with motion. It incorporates precision electric motors that accurately replicate the control forces experienced in-flight. “There are three motors—one for the pitch, one for the roll, and one for the yaw flight controls,” says Chris. “These motors and controllers generate forces that feel exactly like the real aircraft, and their settings will be fine-tuned in collaboration with a PC-12 pilot to ensure maximum accuracy.”

Project Milestones and Next Steps

With most of the panels currently in production, the next phase of the project involves assembling these components into the cockpit. “It’s a bit like waiting for a bus,” Chris notes. “We have been manufacturing multiple components simultaneously, and now everything is coming together at once.” Once installed, the simulator will be handed over to the software team for system integration and final testing.

As the project nears completion, the aviation community eagerly anticipates the launch of this cutting-edge PC-12 simulator. With its combination of authentic components, advanced computing, and precision engineering, the Simuflight PC-12 simulator is set to provide an unparalleled training experience for pilots.

According to Simuflight’s timeline:

- By the end of March 2025, the PC-12 simulator will be substantially assembled.

- Final software integration will follow, ensuring system accuracy and realism.

- Civil Aviation Authority (CAA) evaluation is scheduled for the end of Q2 2025.

- Entry into service for training is expected by Q3 2025.

South Africa’s Leading Simulator Manufacturer

One of the most remarkable aspects of this project is that it is being designed, manufactured, and assembled entirely in South Africa. This highlights the country’s capability and capacity to produce world-class aviation training equipment. According to Alfredo, “Simuflight proudly stands as one of the only commercially-driven, non-military focused companies on the continent capable of such simulator manufacturing”.

With the PC-12 simulator soon to be operational, Simuflight continues to push the boundaries of aviation training, offering pilots cutting-edge technology to advance their skills.

Simuflight’s

PC-12 Simulator:

A New Era in Advanced Flight Training

In a recent Coffee with the Editor session, held at Simuflight in Johannesburg, Managing Director Alfredo Schulz and Project Manager Chris Palfreyman shared insights into the groundbreaking PC-12 simulator project. This state-of-the-art training tool is currently being assembled at their Midrand facility by Aviamech, the group’s simulator engineering company, marking a significant milestone in aviation training in South Africa.

Simuflight, a trusted name

For readers of African Pilot, Simuflight is a familiar name, having established itself as a leading advanced Aviation Training Organisation (ATO) over the past 23 years. However, for the new editor, this visit offered a deeper look into the company’s history and expertise.

Simuflight operates in a niche segment, focusing on pilots who are already qualified and seeking type ratings to enhance their employability and career progression. Unlike entry-level flight schools that train aspiring pilots from scratch, Simuflight caters to corporate clients and experienced pilots looking to transition into new aircraft types.

Simuflight’s existing simulator-based training programs include type ratings for the Caravan 208, a crucial starting point for many young commercial pilots. Over the years, they have expanded their offerings to include the King Air 200 and their flagship training program, the King Air 1900. While Boeing 737 training has been part of their portfolio, that program is currently dormant. However, the biggest excitement at Simuflight in 2025 revolves around the highly anticipated PC-12 simulator.

The Journey to the PC-12 Simulator

The concept for a PC-12 flight simulator was first envisioned 12 to 14 years ago, when industry professionals expressed the need for such a training tool. However, at the time, the project faced significant hurdles—most notably, the lack of a suitable airframe. The breakthrough came two and a half years ago when Alfredo Schulz discovered an available PC-12 airframe, which became the foundation for this ambitious initiative.

Once the airframe was secured, Aviamech’s engineering team embarked on an extensive design phase in December 2023. The challenge was to integrate Aviamech’s proprietary electronics, instrument panels, and software into the cockpit. By mid-2024, the design phase was complete, paving the way for the manufacturing and assembly process.

The Importance of Realism in Training

The simulator, designed to provide pilots with an authentic training experience, is built using a real PC-12 cockpit section to ensure absolute accuracy in form, feel, and function.

Chris highlights that integrating an original airframe into the simulator is key to developing muscle memory among pilots. “All dimensions, distances, and relationships between controls are exactly as they would be in the real aircraft,” he explains. “This is crucial for effective training.” The project began with a full 3D design using modern CAD software to ensure that each component fits seamlessly during the manufacturing phase. This meticulous design and planning prevents time-consuming reworks and ensures a smooth assembly process.

The simulator will incorporate both original aircraft components and custom-built parts.

One of the most intricate pieces being fabricated is the Overhead Panel, a crucial component controlling the aircraft’s electrical systems. “The switches and circuit breakers function exactly as they would in the actual aircraft, including the ability to break electrical flow manually,” Chris highlights. Even the illumination and backlighting mimic the original PC-12 systems.

Avionics and Future Upgrades

The avionics installed in the simulator will match the original PC-12 Type 47, commonly referred to as the Legacy model. These will be computer-generated but will accurately replicate the real aircraft’s avionics suite. The design also incorporates the potential for future upgrades, allowing for an easy transition to more modern avionics configurations. “We have built a growth path into the design,” added Chris. “The simulator can be upgraded to include the latest glass cockpit without altering the airframe.”

Advanced Computing for Ultra-Realistic Simulation

At the heart of the simulator is a powerful network of computers, each assigned a specific function. One system manages aerodynamic and scenery modelling, another controls the visuals, and two others drive the cockpit’s instruments. An Instructor Operating Station (IOS) is also included, allowing trainers to manipulate various in-flight scenarios. “Instructors can simulate engine failures, landing gear malfunctions, and other emergency situations to ensure pilots are prepared for real-world challenges,” Chris explains.

Motion and Control Systems

The simulator is not equipped with motion. It incorporates precision electric motors that accurately replicate the control forces experienced in-flight. “There are three motors—one for the pitch, one for the roll, and one for the yaw flight controls,” says Chris. “These motors and controllers generate forces that feel exactly like the real aircraft, and their settings will be fine-tuned in collaboration with a PC-12 pilot to ensure maximum accuracy.”

Project Milestones and Next Steps

With most of the panels currently in production, the next phase of the project involves assembling these components into the cockpit. “It’s a bit like waiting for a bus,” Chris notes. “We have been manufacturing multiple components simultaneously, and now everything is coming together at once.” Once installed, the simulator will be handed over to the software team for system integration and final testing.

As the project nears completion, the aviation community eagerly anticipates the launch of this cutting-edge PC-12 simulator. With its combination of authentic components, advanced computing, and precision engineering, the Simuflight PC-12 simulator is set to provide an unparalleled training experience for pilots.

According to Simuflight’s timeline:

- By the end of March 2025, the PC-12 simulator will be substantially assembled.

- Final software integration will follow, ensuring system accuracy and realism.

- Civil Aviation Authority (CAA) evaluation is scheduled for the end of Q2 2025.

- Entry into service for training is expected by Q3 2025.

South Africa’s Leading Simulator Manufacturer

One of the most remarkable aspects of this project is that it is being designed, manufactured, and assembled entirely in South Africa. This highlights the country’s capability and capacity to produce world-class aviation training equipment. According to Alfredo, “Simuflight proudly stands as one of the only commercially-driven, non-military focused companies on the continent capable of such simulator manufacturing”.

With the PC-12 simulator soon to be operational, Simuflight continues to push the boundaries of aviation training, offering pilots cutting-edge technology to advance their skills.